Assembly Instructions

IGE Assembly Instructions

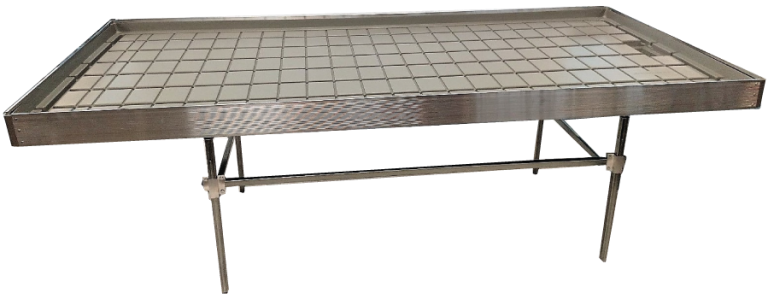

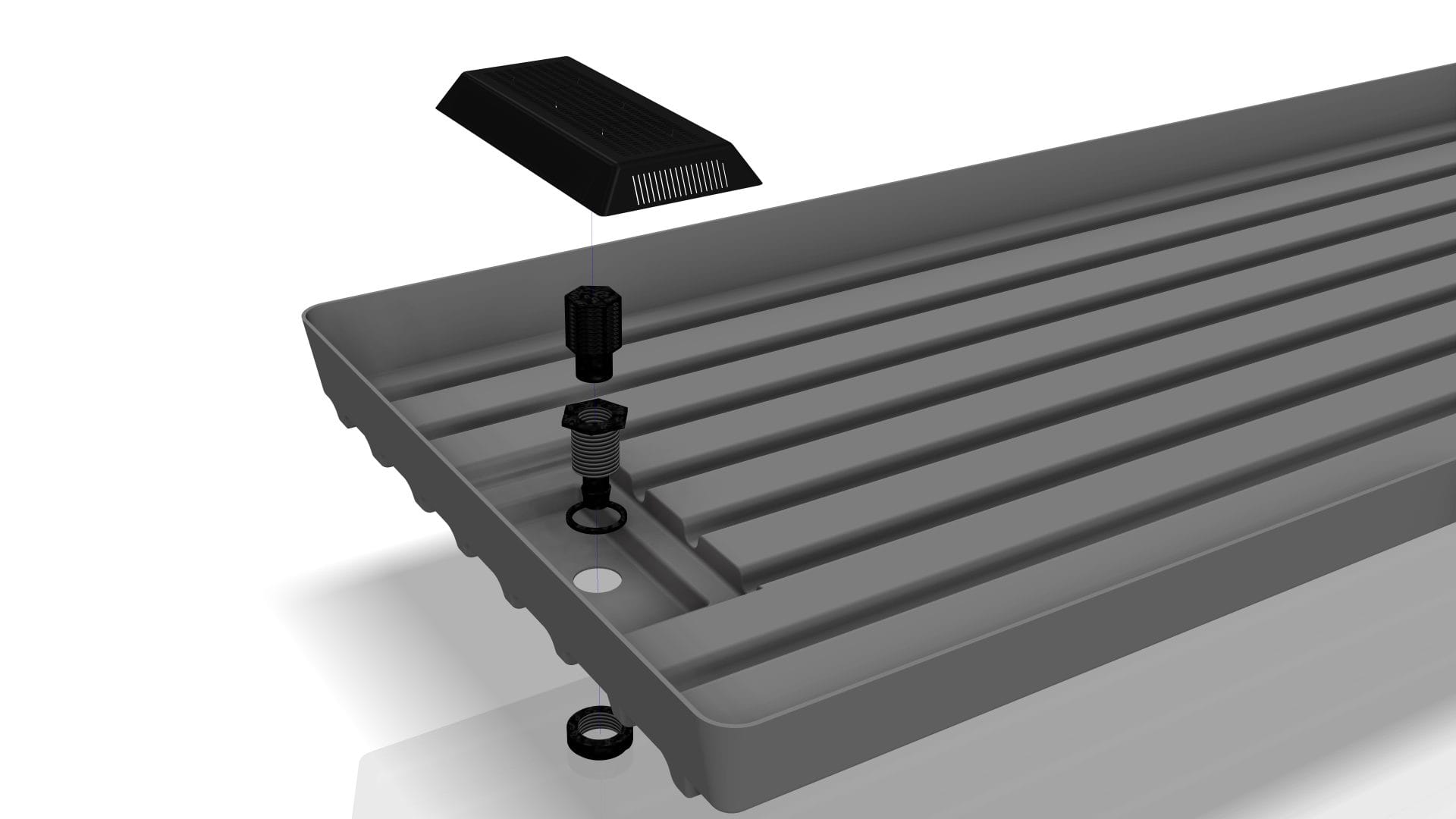

Ebb & Flow Bench Assembly

Track Bench Assembly

Archive & Rolling Rack Assembly

Grow Rack Mobile Cart Assembly

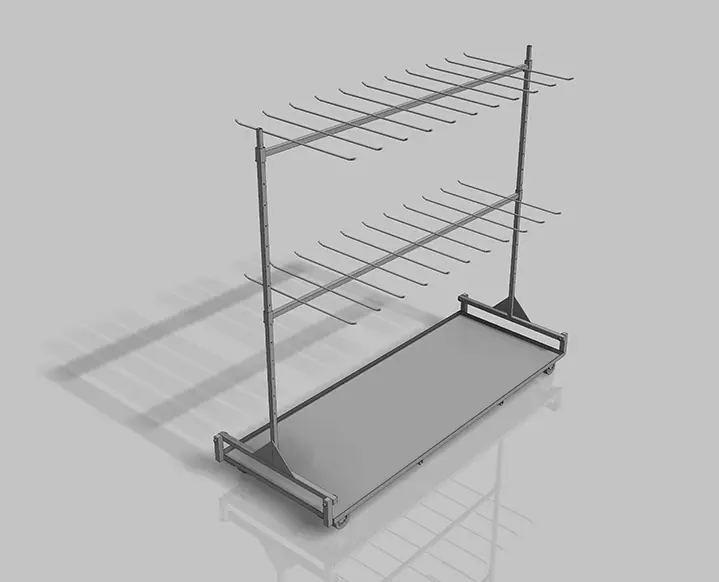

Mobile Dry Rack Assembly

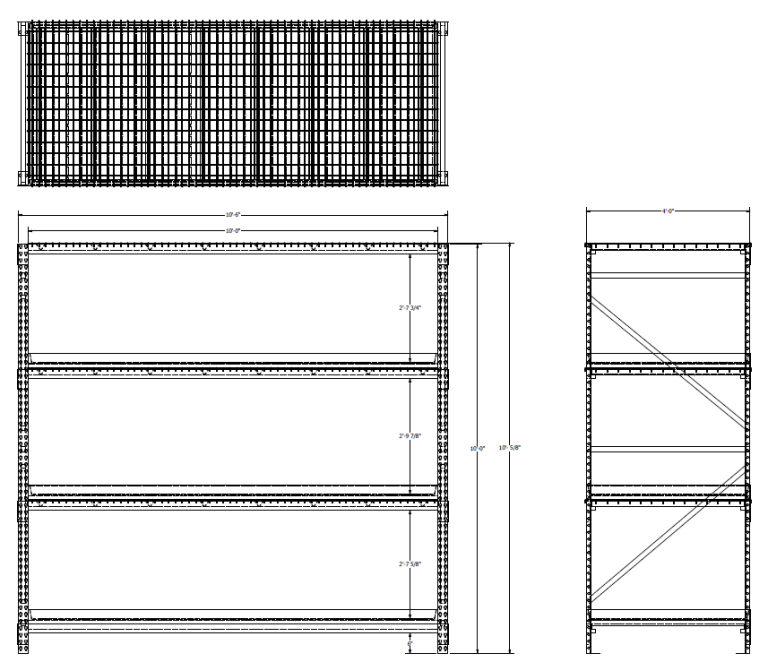

Standard Multi Tiered Benches

Air Flow System Assembly

Plant Support System Assembly

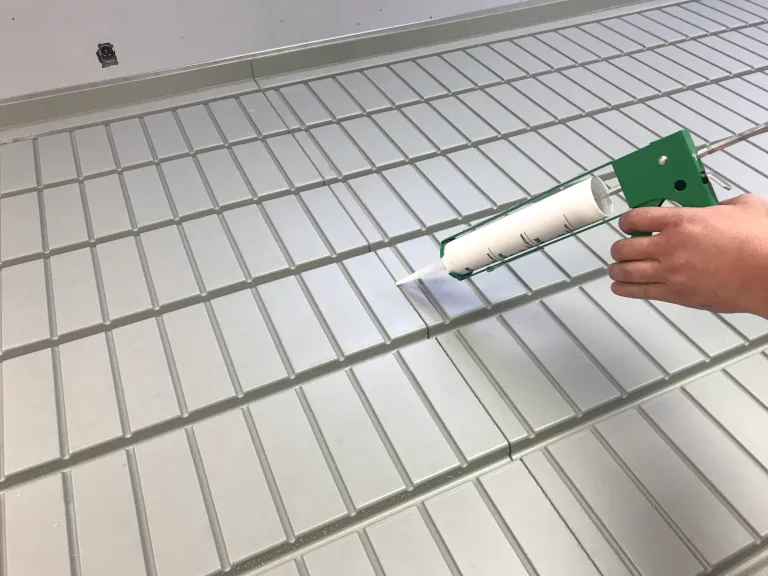

Gluing Instructions

Old-Style Plant Support System

Catwalk System Assembly

Secure Retail Racking System

ITB Mechanical Assist Assembly

Filter and Fitting Instructions